Small Beer Production Equipment

- YUXIN

- China

- 30-40 days

- 500 sets per year

Small Beer Production Equipment of YUXIN

Customized as your idea

Supply drawings, layout, pipeline diagram, loading diagram etc.

Engineer will go there for installation/debugging and training.

Electric/steam/direct fire heated

2vessels, 3 vessels, 4vessels etc.

with agitator

automatic controlled by pneumatic valve

Small Beer Production Equipment

The whole beer equipment is consisted of Mash system, Fermentation system, Cooling system, Control system and CIP cleaning system. The tank of the system all adopts Red copper and S.S 304,and the system also have high automatic control capacity. Simple operation ,PLC automatic control system ,PLC semi-automatic control system.

At the same time if you have requirements, we could design and produce the products you need!

Items | Equipment |

Milling system | Malt miller |

Brewhouse system | Mash/Lauter tun |

Kettle/whirlpool tun | |

Hot liquor tank(optional) | |

Plate heat exchanger | |

Wort pump | |

Wort oxygenator | |

Fermentation system | Fermenter |

Bright beer tank | |

Cooling system | Glycol water tank |

Chiller | |

Glycol water pump | |

CIP system | Alkali tank |

Sterilization tank | |

Water pump | |

Control system | Digital display control system |

1. Brewhouse System

Mash tun, Lauter tun, Kettle, Whirlpool tun in various combination;

Hot water tank and cold water tank for optional in special combinations;

Completely stainless steel integrated work platform;

Sanitary and efficiency wort pump;

All piping and fittings.

2. Fermentation System

Standard stainless steel conical cylindrical fermentation tanks;

Single size or double size as brewhouse is common used in microbreweries;

Tanks quantity is exactly calculated by fermentation cycle for various beers;

All manhole, valves, pressure gauges, fittings etc are included.

3. Cooling System

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing;

Efficiency chillers or refrigerators supply cooling energy;

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger;

All pipes, fitting, insulation materials are included.

4. CIP System

5. Control System

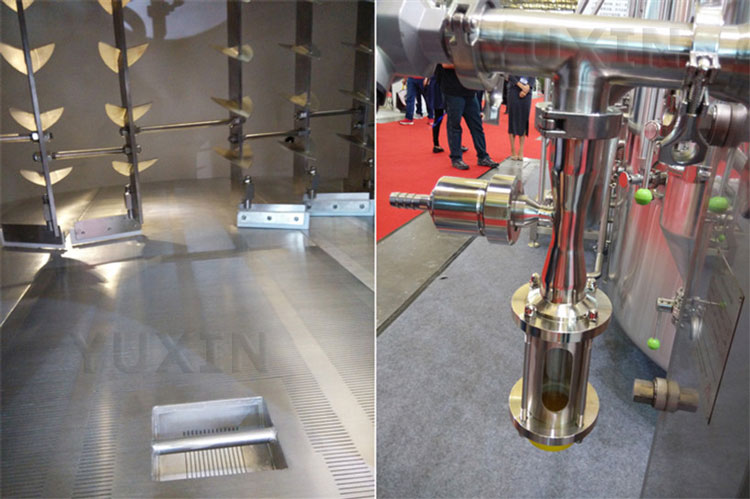

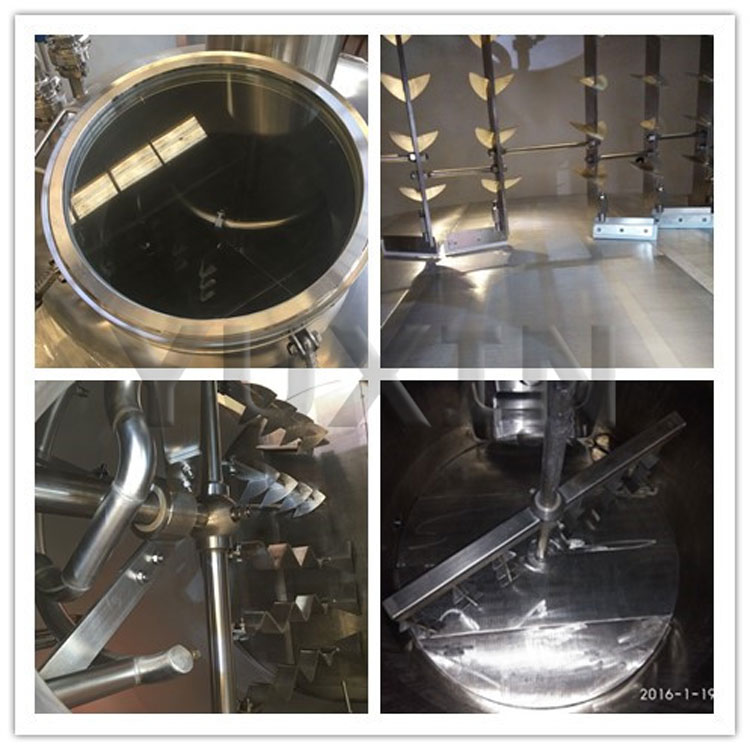

Details:

Details for Polished and Fine welding on the Beer Brewing Equipment /100% TIG WELDING/Automatic Grain System/Sanitary food grade

Packaging & Shipping

Air bubble film, stretching membrane, steel shelf, free-fumigation wooden box, to make everything safe in containers. Suitable for long distance sea transport packaging.

Reference

Up to now, YUXIN equipment has been exported to Russia, USA, Australia, Korea, Europe and other more than 20 countries. For more contact information of our customers, please send us a email.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

Q: How long is your delivery time?

A: Generally single tanks need 30-40 days, for whole plant need 40-50days.

Q: Do you have CE and UL certification?

A: Yes.

Q: What is your terms of payment ?

A: 40% deposit and 60% before delivery.